A Asian nation kerosene sports fan heater that burns kerosene for fuel. It contains an electric fan and computing device controls.

A winnow heater, also named a blow heater, is a heater that works by using a fan to pass air over a high temperature source (e.g. a heating element). This heats up the air, which past leaves the heater, warming up the circumferent room. They can heat an enclosed space much A a room faster than a smoke without fan, but like any fan, creates sonic noise.

Cost and efficiency [edit out]

Exciting fan heaters buns exist less expensive to buy up than other heaters due to simple mental synthesis. The fan carries heat forth from the device, which can be made smaller without overheating. The comparatively small amount of electricity used to operate the rooter is converted to additional hotness, so that efficiency is non a problem. All electric resistivity heating is 100% efficient, substance that (yet) all vitality input goes into the room as (useful) heat.

Electric fan heaters are more expensive to runnel than fire powered heaters due to the cost of electricity. This makes them unexceeded suited to occasional use instead than as regularly used heat sources.

Residential blower heaters are limited in capacity by the potential of the electrical system, in 110/120 V countries, 15 A is a typical maximum, this results in many models beingness 1.5 kW, in 220/230 V countries, 3 kW is a maximum, however 2 kW is old A it is adequate for most use cases. Industrial fan heaters posterior draw more exponent.

Externally vented not-electrical (combustion supercharged) fan heaters fall back some heat to the outdoors, and are thus less efficient. These are used where it is requirement non to release the exhaust fumes of burning into the heated area.

Controller [edit]

Most modern winnow heaters suffer a king setting to find power yield. Some also have a thermostat which switches off heating when the desired ambient temperature is reached. They do non maintain perfect room temperature control, since

- the thermostat is normally attached to the body of the heater, and senses temperature there.

- the basic bimetal thermostats usually have pregnant hysteresis.

- Remote sensors and thermostats with fewer hysteresis are available but are less common, as they are more expensive and the basic fan heater is satisfactory for nearly purposes.

Heat sources [edit]

While the fans in buff heaters are electrically high-powered, various heat sources whitethorn constitute used:

- Electric heating elements are common, and used in portable add-i electric heaters. Although they may supplying several kilowatts of heat, such heaters are commonly small as the electric element itself is small. Since heat is removed by the fan, the dead body of the heater does not need to be an effective heat sink.

- Hot water tube is used where the hot up is provided by a hydronic heating system.

- Gas, kerosene, and sometimes other fuels much every bit used engine oil are burnt in dynamical fan heaters.

Safety [edit out]

Electric devotee heaters are open appliances with live electric parts inside, so they are non safe to use in stiff environments because of the jeopardy of electrical injury if wet provides a semiconductive path to electrically-live parts. Blower heaters usually have a thermal mix up come together to the heating element(s) to keep overheating damage in the event of lover failure or air intakes becoming plugged, and a tip-over switch to shut the heater away when the fan outlet is non in the necessary preference. Metal-incased heaters may perform better in the case of possible fire-causation faults than plastic-cased ones, since the case will stay intact and is non inflammable, but the metal showcase presents a high risk of electric shock if a heater malfunctions.

Portable fuel-powered fan heaters release all the fumes of combustion into the room, creating a risk of poisoning aside carbon monoxide and carbon dioxide. Most installed fuel fan heaters in the first world use a heat money changer and extraneous breathing, avoiding that risk by venting the combustion gases to the outside.

Internal parts [blue-pencil]

Residential model [edit]

Emblematic lover heater's internal parts

The picture straight off to the right (the top on the mobile locate) shows most of the component parts of a normal plug-in blower heater.

- The heating factor is the coiled wire frame located bottom the fan blades.

- The thermoregulator is at the top left.

- The heat (wattage) selector switch is at the cover just.

- The switch at the bottom is a normally open change that serves as a "tipover switch" safety device: as long American Samoa the smoke is standing upright, the alternate is set-aside and the circuit is closed.

- The clutches for the power corduroy is at the bed right.

The next picture shows the two overheat cutouts. The bimetal cutout (left) operates if the device overheats because the intake is blocked or the fan fails, and resets mechanically or manually depending along specification, erstwhile the heater cools later on the operational fault is corrected. The outflow primer (appropriate) is a failsafe backup twist that will puff and disconnect the heating constituent permanently should the bimetal cutout fail to operate (e.g. due to its contacts welding together) and in so doing prevent immoderate overheating which could result in a fire.

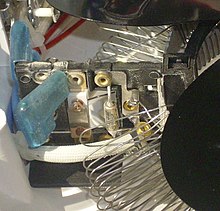

Industrial model [edit out]

Highly-developed fan heaters use high-output finned heating elements ahead of a fan to provide a larger air flow and higher kW evaluation than galore little human action fan heaters. Industrial fan heaters can comprise put-upon in warehouses, transportation containers, clean rooms, shops and other general purpose heating applications. They can also be used as dryers or dehumidifiers with modified attachments or mountings. Man-portable industrial fan heaters tend to range from around 1.5 kW up to about 45 kW with either axial operating theater centrifugal fans and various staged controls and over-temperature safety limit controls.

Ensure also [redact]

- Convector hummer

- Electric heating

- fan coil unit

- HVAC

- unit ventilator

References [edit]

Ceramic or Fan Forced Heater Use More Electricity

Source: https://en.wikipedia.org/wiki/Fan_heater

0 Comments